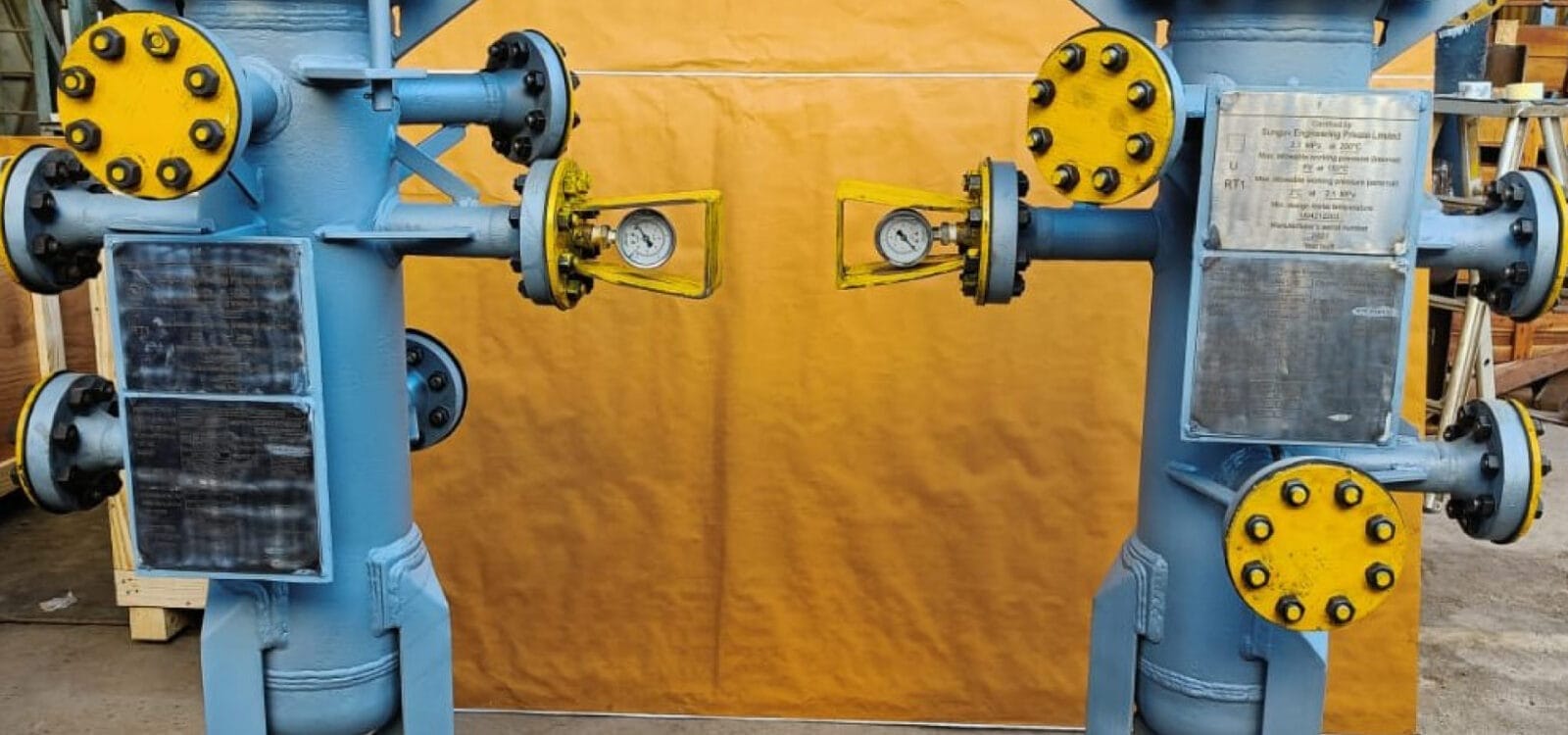

One of the most important components in industrial processes is the filtration packages. Filters ensure that the contaminants are removed on time and will protect equipment, enhance efficiency and meet regulatory standards. Industries such as petrochemicals, power generation and oil and gas rely heavily on tailored solutions from filtration package manufacturers such as Sungov Engineering to address their specific needs. For instance, amine filtration systems are crucial in gas-sweetening processes, removing particulates and hydrocarbons from amine solutions to prevent equipment corrosion and optimize process efficiency. In the same way, fuel gas filters play a pivotal role in ensuring a clean fuel supply by eliminating impurities like moisture and particulates, and safeguarding turbines and other sensitive equipment.

The materials and technologies employed in these systems, such as the use of stainless-steel filter cartridges, further underscore their importance. These cartridges are valued for their durability, corrosion resistance, and high-temperature tolerance. This makes them ideal for demanding industrial environments. Sungov Engineering, a leader among filtration package manufacturers, offers both standard and customized solutions, providing industries with the flexibility to address unique challenges. By investing in high-quality filtration systems, you can be sure of reducing downtime, lower maintenance costs, and ensuring compliance with environmental and operational standards. This ultimately drives better performance and long-term sustainability.

What are the Key Features You Should Look Out for When Choosing an Effective Filtration Package

There are a few key features that you will need to look out for when you are about to choose an effective filtration package. Here are a few points that we have listed to make it simple for you:

- High Filtration Efficiency: You must look out for filters that can remove a wide range of contaminants with minimal loss of pressure.

- Durability and Reliability: Filters must be constructed with robust materials such as stainless steel to withstand high pressures, temperatures, and corrosive environments.

- Customizability: The filters you choose must be tailored to meet specific industry requirements that include flow rates, contaminant types, and space constraints.

- Ease of Maintenance: You must look out for filters that are designed for quick access to filter elements and those that can reduce downtime during replacement or cleaning.

- Compatibility with Multiple Applications: Filters should be suitable for a variety of processes, such as gas processing, water treatment, and fuel filtration.

- Compact and Modular Design: Should be space-efficient and scalable to fit different plant sizes and operational demands.

- Regulatory Compliance: Should be able to meet industry standards like ASME, API, or ISO for safety, efficiency, and environmental protection.

- Cost Efficiency: The filter must minimize operational expenses by offering a long service life, energy efficiency, and reduced replacement frequency.

- Advanced Filtration Media: It must be able to incorporate high-performance cartridges or coalescing filters for optimal separation and extended usability.

- After-Sales Support: The filter you purchase must be backed by reliable technical assistance, availability of spare parts, and extended warranties.

How is Customization Solution Different from Standard Filtration Solutions

Businesses have an eternal critical choice to make when choosing a filtration system for their processes. The choice between standard solutions and customized filtration packages. The standard filtration solutions are pre-designed and readily available. They offer cost-effective and time-efficient options for applications with common operational needs. These solutions are ideal for industries where requirements like flow rates, contaminant types, and operational pressures fall within standard parameters. However, they have a downside too. They may lack the flexibility to address unique challenges, such as unconventional installation spaces, highly specific contamination profiles, or industry-specific regulations.

This is where customized filtration solutions come into the picture. They are tailored to meet the precise demands of a process or application. These systems provide enhanced performance by optimizing elements like flow capacity, filtration efficiency, and material compatibility. For instance, industries that deal with aggressive chemicals or extreme temperatures may benefit from customized components, such as corrosion-resistant stainless steel filter cartridges or multi-stage filtration setups. Customization also enables integration with existing infrastructure and reduces the need for major system overhauls. While tailored solutions often involve higher upfront costs and longer lead times, their ability to address niche requirements, improve efficiency, and minimize downtime makes them a valuable long-term investment.

The choice between customization and standardization finally depends on operational priorities. Some businesses need to weigh factors such as budget, timelines, and specific filtration challenges to determine the most suitable approach that works for them.

Sustainable and Environmental Considerations to Bear in Mind when Choosing a Filtration Package

In the design and implementation of modern systems, industrial processes, infrastructure and consumer products, sustainability and environmental considerations are increasingly critical. Businesses and organizations are focusing on reducing their environmental footprint by adopting eco-friendly practices and technologies. For instance, filtration systems now incorporate sustainable materials such as reusable stainless-steel cartridges and energy-efficient designs to minimize waste and resource consumption. There is a lot of emphasis that is placed on reducing emissions, conserving energy, and adhering to regulatory standards for environmental protection. In addition to this, sustainability drives innovation, encouraging the development of closed-loop systems that recycle waste products or repurpose them for other applications. These practices not only ensure compliance with environmental guidelines but also align with global efforts to combat climate change and preserve natural resources for future generations. By prioritizing sustainability, industries can achieve long-term economic benefits while contributing positively to the planet.