A significant challenge that various industries face is the threat of corrosive environments. Be it chemical processing plants or offshore oil rigs to water treatment facilities and marine operations. When there is exposure to aggressive chemicals, saltwater, high humidity, and extreme temperatures, these harsh conditions are generated. These conditions can rapidly degrade conventional materials, which leads to equipment failure, costly downtime, and safety risks. Corrosion not only affects operational efficiency, but it can reduce the lifetime of critical components. It is only necessary that you select the right kind of filtration system, when faced with such demanding settings. Having the correct filtration system ensures that performance and reliability goes hand in hand. This is why corrosion-resistant solutions like stainless steel basket filters is a choice of many.

What are Stainless Steel Basket Filters?

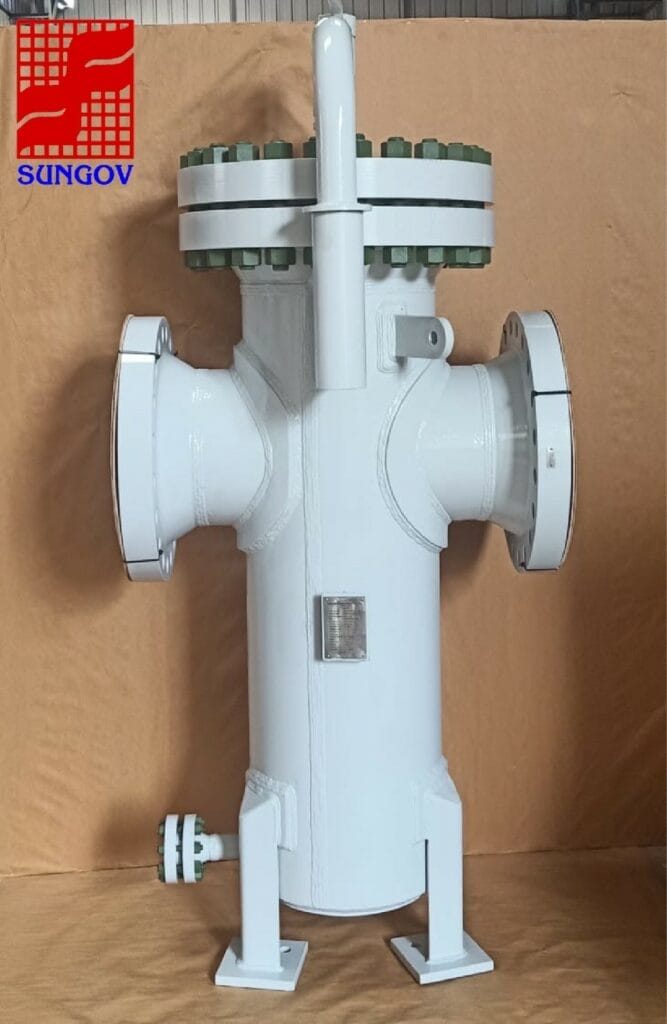

Robust filtration devices that can remove debris, contaminants and particulates from liquids and gases are generally stainless-steel basket filters. These filters comprise of a perforated mesh-lined basket that traps unwanted material and allows only clean fluid to pass through. Stainless steel basket filters are well-known for their strength, durability and most importantly, corrosion resistance. This is why stainless-steel basket filters are a preferred choice when the environment is harsh, such as chemical exposure, extreme temperature and moisture.

The most in-demand variant is the duplex basket filter strainer, which consists of two parallel filter chambers. The design of this basket filter strainer is conducive to non-stop operations. This is because it allows for one basket to be cleaned or replaced while the other works, without the need for a down time. It makes this variant of basket filter to turn highly efficient and have uninterrupted flow of operations.

When you begin your search for a reliable filtration system, it is important that you choose products from reputable basket filter manufacturers such as Sungov Engineering who consider it primary to adhere to strict quality standards. A trusted basket filter supplier can help provide customized solutions that are tailored to specific industrial applications. You will need a supplier who will ensure basket filters for optimal performance, reduced maintenance, and extended equipment life. Whether it is for petrochemical plants, water treatment facilities, or food processing units, stainless steel basket filters can offer a dependable solution for maintaining fluid purity in corrosive environments.

Durability and Longevity: Why Stainless Steel Outperforms Other Materials

When it comes to durability and longevity, stainless steel stands out as a superior material compared to traditional options like carbon steel, plastic, or cast iron. Its inherent strength and resistance to wear, corrosion, and extreme temperatures make it ideal for demanding industrial applications. Stainless steel basket filters can withstand high-pressure environments, aggressive chemicals, and mechanical stress without cracking, warping, or degrading over time. Unlike plastic filters that may become brittle or metal filters prone to rust, stainless steel retains its structural integrity even under continuous operation in harsh conditions. This long-lasting performance reduces the frequency of replacements, minimizes downtime, and lowers maintenance costs, offering a better return on investment. Stainless steel’s ability to resist fouling and contamination ensures consistent filtration efficiency, making it the preferred choice for industries that prioritize reliability, such as oil and gas, chemical processing, and marine operations.

Environmental and Economic Benefits of Using Stainless Steel

There is significant environmental and economic benefits when using a stainless steel basket filter. This is why stainless-steel basket filters are a sustainable choice in many industries that focus mainly on eco-friendliness and efficiency. When looking at the environmental perspective, you can be sure that stainless steel is 100% recyclable, which helps reduce waste and conserve natural resources. Since it has the ability of a large lifespan, the need for frequent replacements decreases drastically. This has a great environmental impact that is associated with manufacturing, transportation, and disposal of filtration components. In addition to this stainless steel’s resistance to corrosion and chemical degradation reduces the risk of leaks and contamination. This helps in promoting cleaner, safer operations in industries such as water treatment, chemical processing, and oil and gas.

The durability and low maintenance requirements of stainless-steel basket filters over a period of time help you save costs although the initial investment may be higher than filters made from less durable materials. However, the need for repairs, downtime and replacements can help you lower the operational costs. This combination of environmental sustainability and long-term cost efficiency makes stainless steel an invaluable material for modern industrial filtration systems.

The location of installation of these Basket Filters are UAE