Large industrial plants utilize significant amount of water for various purposes. These include cooling water in power plants and sea water intake in desalination plants.

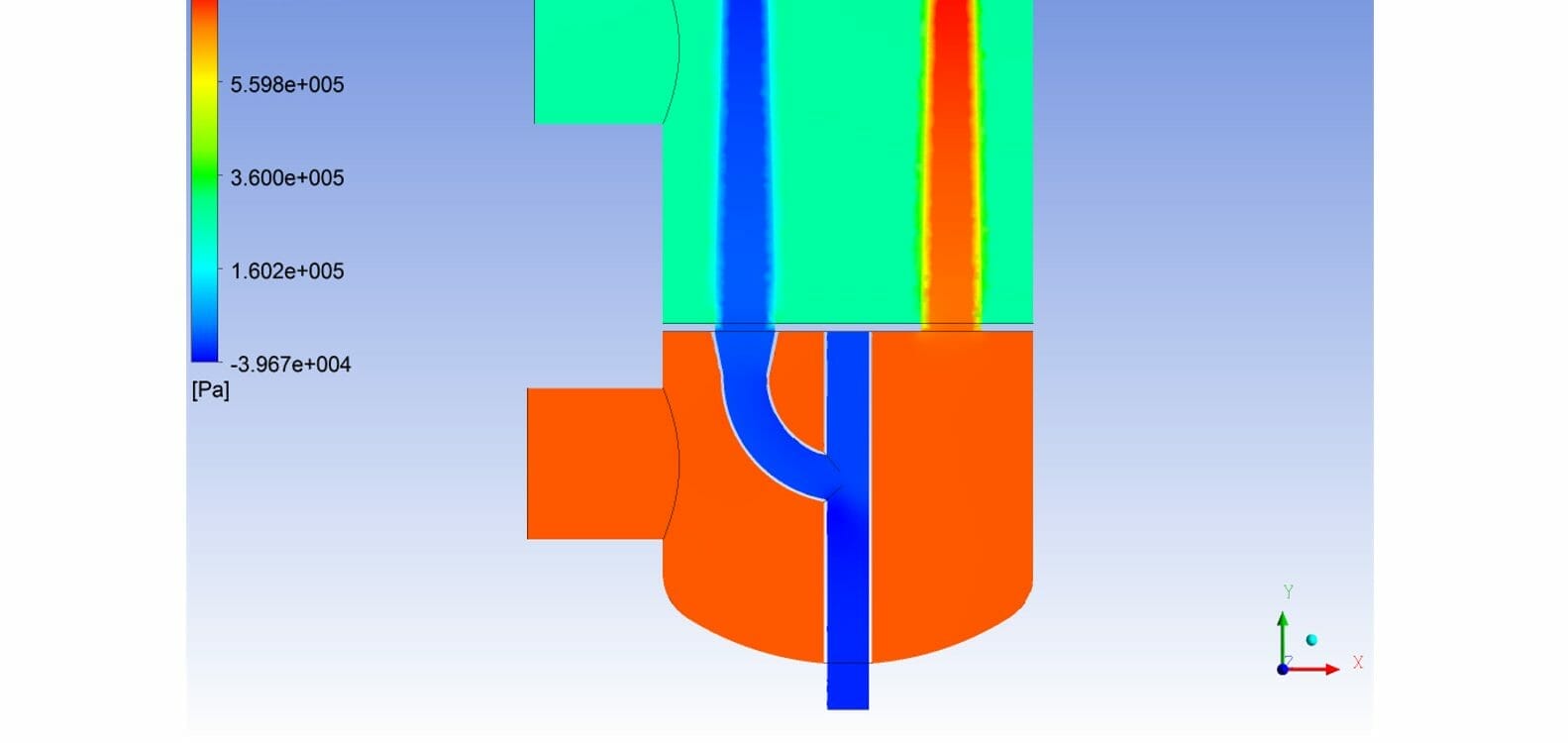

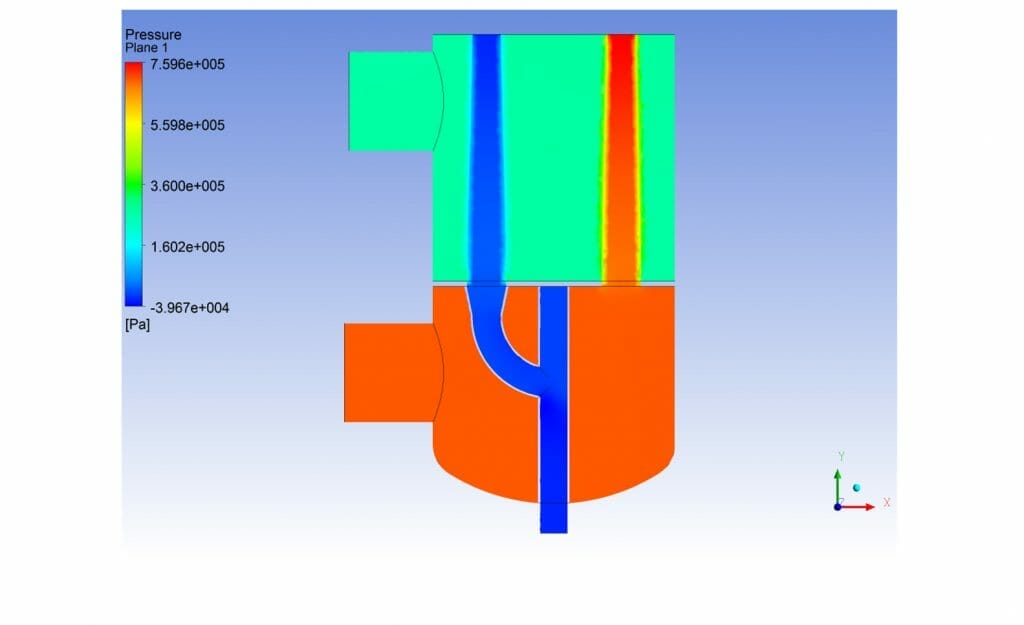

Due to the critical nature of these fluid circuits and the high incidence of solids contamination. The filtration technology employed for treatment of such water is Online Automatic Backwash Filters (also called as Online Self-Cleaning Filters). The science behind Automatic Backwash Filters is simple: fluid always flows from high pressure zone to low pressure zone. For a system under positive operating pressure, once the backwashing pipeline (the component rotating in the video above) is opened to atmosphere. The tendency of the fluid is to rush to this pipeline sucking along with it, the impurities held inside the filtering elements (the holes in the video above). Thus, regenerating the filtering elements for further fluid filtration.

A key aspect of the efficient working of this technology is automation triggered by a signal from the differential pressure transmitter mounted on the filter vessel. This signal actuates the opening of the drain valve to the atmosphere and starts the motor drive of the backwashing pipeline. All of this automation can either be operated locally using a PLC control panel near the equipment or remotely using appropriate control logic at the plant DCS (Distributed Control System).

Sungov has extensive experience in offering this filtration technology to several international clients. Sungov’s engineering team designs products with energy efficiency in mind as part of our continuous commitment to environment protection vide our ISO 14001 certification objectives. The example shown above uses only a 90W motor to move 100+ kg backwash pipeline components against high salinity seawater flow of ~2 m/s to achieve cleaning-in-place of filtering elements. The materials used are austenitic-ferritic (duplex) stainless steel for improved resistance to sea waterway corrosion as well as rubber-lined components. This particular example was a supply to a Saudi Arabian petrochemical company.