Fuel Gas Filters: Protecting Industrial Equipment from Contaminants and Wear

If you are looking to extend the lifespan of your industrial equipment, then investing in the right fuel gas filter system can be your answer. Be it a dry gas filter for solid impurities or a natural gas filter cartridge for precise filtration, the benefits are clear: reduced wear, lower maintenance costs, and uninterrupted operations.

What you need to imagine is a high-performance car that runs smoothly on fuel. Now, imagine this, impurities clog the fuel system. What can happen? The engine sputters, efficiency drops, and wear accelerates. The same principle can be applied to industrial equipment relying on fuel gas too. Contaminants in fuel gas can wreak havoc, causing damage, inefficiency, and costly downtime. This is where you will find the importance of fuel gas filters, the unsung heroes of industrial operations.

Why Is It Necessary to Have a Fuel Gas Filter?

When it comes to industrial processes, we know that they often rely on natural gas or other gaseous fuels. These fuels often carry contaminants such as dust, oil, and moisture. When there is no proper filtration, these impurities can damage sensitive equipment, including turbines, compressors, and burners. Fuel gas filters are your first line of defense as they can ensure that clean, dry gas reaches your equipment. These filters work in harmony with natural gas filter cartridges, offering high filtration accuracy for a variety of applications.

Contaminants like fine particulates and corrosive elements accelerate equipment wear by eroding internal components or causing chemical reactions. By employing advanced filtration, such as stainless-steel filter cartridges, you can ensure the following:

Protect Moving Parts: Prevent abrasive particles from damaging bearings, seals, and rotors

Reduce Corrosion: Trap moisture and corrosive elements before they reach critical systems

Enhance Operational Efficiency: Clean fuel gas ensures smooth operation and optimal performance

What is the Importance of Materials and Technology in Fuel Gas Filters

We have to understand that not all filters are created equally. It is the choice of materials that significantly impacts the durability and performance of a filter. When you have a stainless-steel filter cartridge, for instance, you can be sure of the following:

High durability: Resistant to corrosion, ensuring a long service life

Excellent Filtration Precision: Capable of capturing ultrafine particles

Low Maintenance: Designed to withstand high pressures and temperatures without frequent replacements.

Key Features and Benefits of Effective Fuel Gas Filters for Industrial Operations

We have listed the most important key features of fuel gas filters. So, read on:

High Filtration Efficiency

When you are looking for a fuel gas filter, you must keep in mind that it must be efficient at removing contaminants like particulates, oil droplets, and moisture from the gas stream.

Durable Materials

Filters crafted with stainless steel filter cartridges offer exceptional strength, corrosion resistance, and longevity, making them ideal for demanding environments.

Versatility

Whether you’re dealing with high-pressure pipelines or varying flow rates, effective filters must be able to adapt to different operating conditions. Options like dry gas filters are designed to handle diverse applications.

Ease of Maintenance

Effective filters are engineered for minimal downtime. Features such as easy cartridge replacement and robust designs ensure long intervals between servicing.

Compact Design

Space constraints are common in industrial setups. Compact yet high-performing filters fit seamlessly into existing systems without sacrificing efficiency.

The Benefits of Fuel Gas Filters for Industrial Operations are listed below:

Enhanced Equipment Longevity

By removing harmful contaminants, fuel gas filters prevent wear and corrosion in turbines, compressors, and other critical components, extending their operational life.

Operational Efficiency

Clean gas ensures consistent performance, reducing the risk of inefficiencies caused by clogged or damaged equipment.

Reduced Maintenance Costs

With fewer breakdowns and longer-lasting components, industries can save significantly on maintenance expenses.

Improved Safety

Removing contaminants reduces the risk of malfunctions and hazards, ensuring a safer working environment.

Compliance with Standards

Effective filtration systems help industries meet stringent environmental and operational regulations, avoiding penalties and enhancing reputation.

What are the Future Trends in Fuel Gas Filter Technology

The drive for the evolution of fuel gas filter technology is definitely the growing demand for higher efficiency, sustainability, and adaptability in industrial operations. When we look at future advancements, we must focus on the integration of smart monitoring systems, enabling real-time tracking of filter performance and predictive maintenance.

Materials like advanced alloys and nanotechnology-enhanced coatings are set to improve the durability and filtration precision of stainless-steel filter cartridges. In addition to this, eco-friendly designs, such as reusable and easily recyclable natural gas filter cartridges, that strive for greener operations will become the paradigm. Innovations in modular and compact dry gas filters will also accommodate space-constrained setups while maintaining high filtration efficiency. As industries continue to prioritize operational excellence and environmental compliance, these emerging trends will redefine the standards for fuel gas filtration.

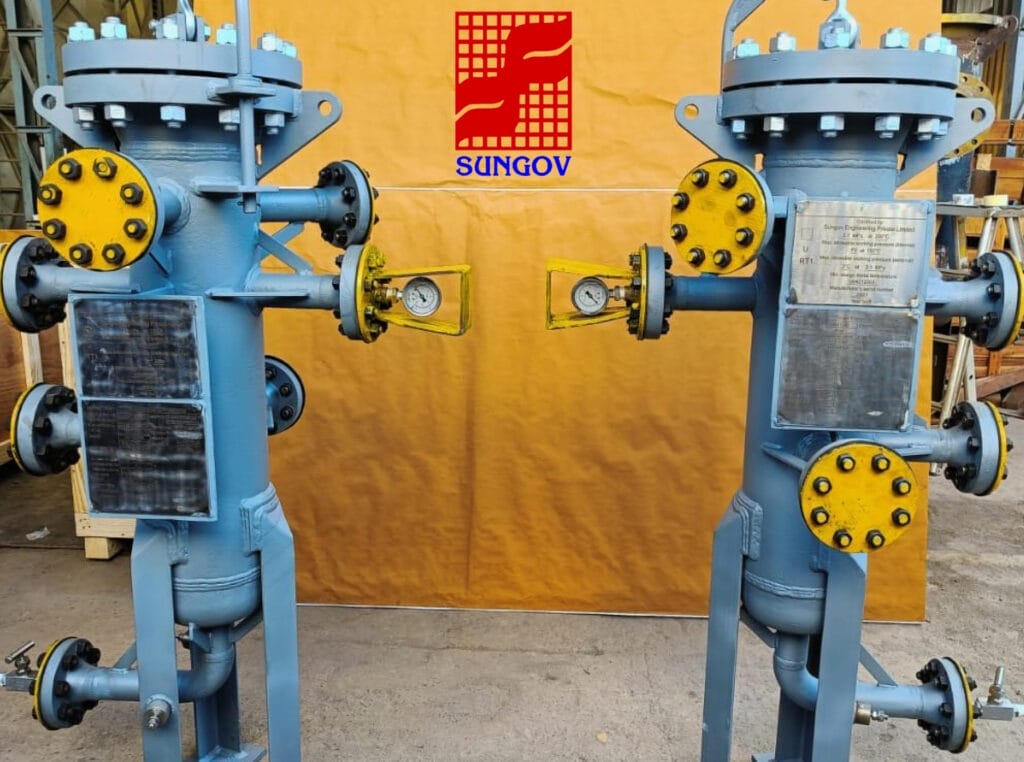

Selecting the right fuel gas filter for your operations is more than just a technical decision; it’s an investment in your equipment’s health and your facility’s productivity. With features like stainless steel filter cartridges and dry gas filters, you can achieve optimal performance while minimizing costs. Equip your systems with the best and experience the difference that a reliable fuel gas filter such as the ones from Sungov Engineering can make.