The primary keys in industrial filtration are efficiency and reliability. Cartridge filters play a vital role in removing contaminants and ensuring smooth operations. But how exactly do these cartridge filters work? Let’s break the understanding down in simple terms.

A cartridge filter is a cylindrical filtration device that is designed to trap impurities from fluids as the fluid passes through. It consists of a porous filter enclosed in housing. This allows for efficient separation of unwanted particles. These filters are widely used in industries such as oil & gas, chemicals, pharmaceuticals, and water treatment.

The filtration process is straightforward. The unfiltered liquid enters the filter housing. As the liquid flows through the filter media, contaminants such as dirt, debris, and fine particles get trapped, allowing only clean fluid to pass through. Liquid cartridge filters are commonly used to remove sediments, rust, and organic impurities from water, fuels, and chemicals.

Cartridge filters can be classified based on their filtration mechanism. Surface filtration captures particles on the outer layer of the filter and is ideal for applications where large contaminants need to be blocked. Depth filtration, on the other hand, traps contaminants throughout the thickness of the filter media, providing a higher dirt-holding capacity.

These filters are essential for industrial applications due to their high filtration efficiency, easy maintenance, and versatility. They help maintain cleaner fluids and gases, protect equipment from damage, and ensure smooth operational performance.

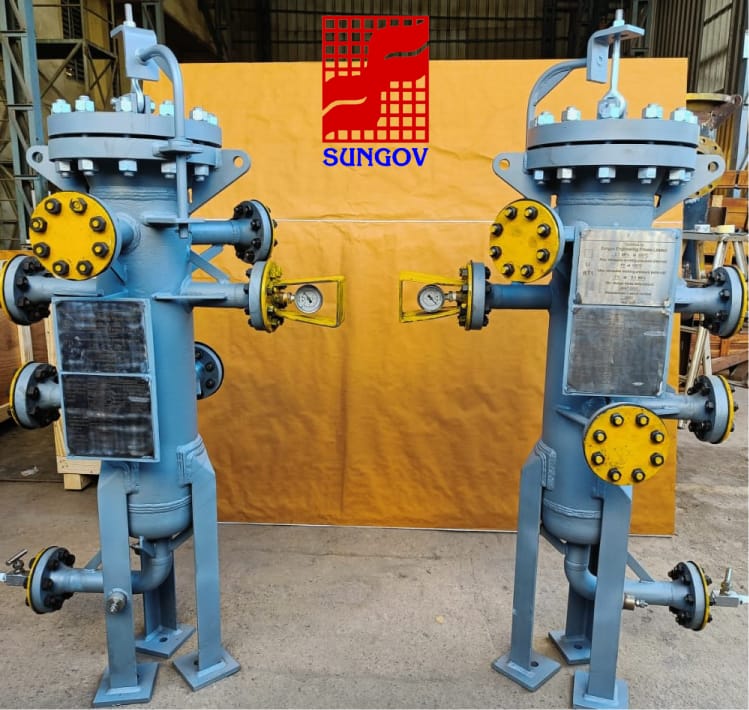

Whether you’re looking for a liquid cartridge filter or a natural gas filter cartridge, investing in the right filtration system can significantly improve efficiency and equipment longevity. If you are looking to choose the right cartridge filter for your application, your search ends with Sungov Engineering. Feel free to reach out!

What Are the Benefits of Using Cartridge Filters in Industrial Applications

Industries can achieve better and cleaner operations using cartridge filters. Let us look at the few benefits of using cartridge filters:

- High Filtration Efficiency – Effectively removes fine particles, dirt, and contaminants from liquids

- Versatile Applications – Suitable for filtering water, fuels and chemicals across multiple industries

- Enhanced Equipment Longevity – Prevents debris buildup, reducing wear and tear on industrial machinery

- Improved Process Efficiency – Ensures clean fluids every time, leading to smoother operations and better product quality

- Easy Maintenance and Replacement – Simple to install and replace, minimizing downtime and maintenance costs

- Compact and Space-Saving Design – Requires minimal installation space while delivering high-performance filtration

- Cost-Effective Solution – Reduces operational costs by extending the life of industrial equipment and minimizing filtration downtime

- Customizable Filtration Options – Available in different materials and filtration ratings to suit specific industrial needs

What Must Be the Factors to Consider When You Select a Cartridge Filter

Choosing the right cartridge filter is essential for ensuring effective filtration, reducing maintenance costs, and enhancing the longevity of industrial equipment. Whether selecting a liquid cartridge filter for fluid filtration or a natural gas filter cartridge for gas purification, there are several key factors that must be considered. Let us look at each one in detail:

Filtration Efficiency & Micron Rating – The size of the particles the filter can remove is determined by micron rating. Finer filtration (lower micron ratings) is ideal for applications that require high purity, while larger micron ratings work well for coarse filtration

Filter Media Material – Cartridge filters come in various materials, such as polypropylene, cellulose, fiberglass, and stainless steel. The choice depends on the type of contaminants, chemical compatibility, and temperature requirements

Flow Rate & Pressure Drop – The filter must accommodate the system’s required flow rate without causing excessive pressure drops, which can impact efficiency

Contaminant Load & Dirt-Holding Capacity – If the system handles high levels of contaminants, a filter with a greater dirt-holding capacity will reduce the frequency of replacements and downtime.

Operating Temperature & Chemical Compatibility – It is very important to ensure that the filter material can withstand the temperature and chemical conditions of the process to prevent degradation or failure

Housing Compatibility & Installation Requirements – The filter should fit seamlessly into the existing filtration system, with easy installation and replacement features

Application-Specific Requirements – Different industries, such as oil & gas, pharmaceuticals, or food processing, may have specific filtration standards and regulations that influence the choice of cartridge filters.

What are some of the Common Challenges in Cartridge Filtration and How to Overcome Them

Cartridge filtration systems are widely used in industrial applications, but they come with certain challenges that can impact efficiency and performance. One common issue is filter clogging. This occurs when contaminants accumulate, leading to increased pressure drop and reduced flow rate. You can manage this by selecting liquid cartridge filters or natural gas filter cartridges with a higher dirt-holding capacity and implementing a regular maintenance schedule. Yet another challenge is the compatibility with process fluids. Some filter media may degrade when exposed to harsh chemicals or extreme temperatures.

Choosing filters made from chemically resistant materials, such as polypropylene or stainless steel, can help prevent this issue. Frequent replacements can drive up operational costs if the wrong filter type is used. Opting for durable, high-efficiency cartridge filters designed for longer service life can minimize downtime and maintenance expenses.

Why Cartridge Filters Are Essential for Industrial Efficiency

Cartridge filters play a crucial role in ensuring cleaner fluids and gases, protecting industrial equipment, and maintaining seamless operations across various industries. Whether used as liquid cartridge filters to remove sediments and impurities from water, fuels, and chemicals or as natural gas filter cartridges to eliminate dust and contaminants from gas streams, these filtration systems enhance overall efficiency and reliability.

By selecting the right cartridge filters and maintaining them properly, businesses can optimize filtration and achieve long-term operational success. Investing in quality cartridge filtration is not just a necessity — it’s a smart strategy for industrial efficiency.